Rowandale Canal Basin - Development History of Section Two

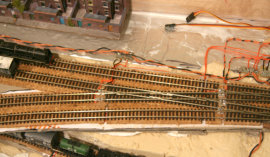

As before the base is made from

two 50mm slabs of builders

insulation board, glued together

with Evostik Impact Adhesive.

The top surface is the zero base

level for the track, and will align

vertically with the goods yard area

of the first section. This provides a

light and rigid base; the same

technique was used for the first

section.

Other layers of board are glued to

this to give elevated track and

background hills, and river valleys

will be cut into it. The top photo

shows the initial rough cut with a

print out of the track.

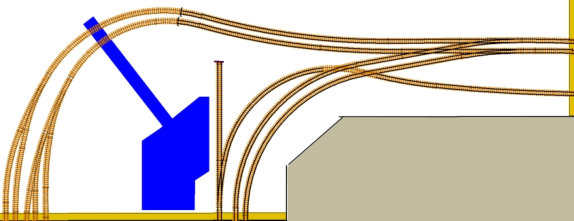

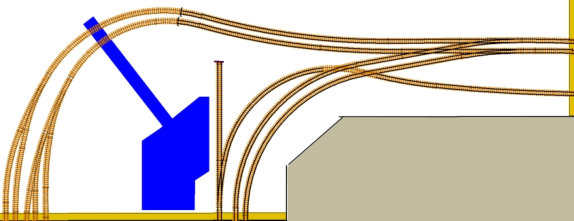

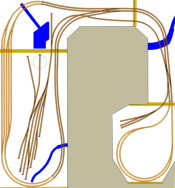

This is the track plan for the five foot corner section which attaches to the

open end of the first town & station section. This will contain an extension

of the town, together with a section of canal, with lock & canal basin.

Then moving into open moorland with the track rising on a 2% to 3%

gradient. At the left are the ends of the hidden storage loops which become

the double main line, which rises to join the other part of the main line

coming from the raised station. The single track access to the goods yard

passes under this and will rise to join the main line in the next section.

This section was started in November 2018.

The mill building and a castle or folly have been build from card

kits, ready to place on it. A low relief terrace of houses, from the

rear of Archie’s Yard, will also be moved to this section.

The plywood side panels have been

glued to the foam base with a building

adhesive ( Everbuild StixAll) This has

high-grab and excellent gap-filling, so

where the vertical edges of the foam

base are inevitably far from exact, the

glue forms a good joint. Corners are

reinforced with right angle mouldings.

Rather than use thin MDF as the base

for the track, a double layer of 3mm

grey-board has been used; glued

together with a PVA based

woodworking adhesive. The grey-board

was cut from A3 sheets with the joints

staggered ( as in brick laying ). This was

much easier to cut to shape than MDF

and results in a strong but slightly

flexible base; ideal for gradients. The

grey-board was then glued to the foam

base with the building adhesive.

The usual cork strips were then glued along the track line with

a generous layer of Copydex adhesive, and the track glued on

top of this with just a thin layer of Copydex, weighted down

with large paint cans or books till dry. Laid like this the track

can easily be lifted, if required, by sliding the full blade of a

snap-off blade craft knife underneath it.

Further work on this section will be postponed until the base layers and track is laid for the

remaining sections. The alignment dowels and clamping magnets have not been fitted yet.

So that trains can be run again as soon as possible, these sections will

initially just have the track bases, track laid and ballasted, together with basic

topography. Points control and isolation sections will then be connected to the

computer for route selection from the control panel. Buildings and scenery

will then be added to each section in turn.

The development of the sections of Rowandale; are each recorded on separate pages.

Not much modelling work has been done over the summer. However the layout has now moved upstairs to

a spare bedroom and the shape of the planned extension layout has been changed from a long ‘L’ to a more

compact ‘U’ shape. The supporting frame has been built and all three of the new sections have been

constructed. The track has been laid to all the new sections and the tracks aligned across the baseboard

joints.

This corner section will now feature

a canal lock with lock-keeper’s

cottage and canal basin.

The lock, cottage and one narrow

boat have been constructed; again

from Scalescenes card kits, and can

be seen in detail here on the

Buildings Page.

The basic topography on Section Three will be brought to this same level

before further work done to finish this section.

Baseboard sections are aligned with two engineering dowel pins & sockets, and

held together with two 25mm diameter magnets (22kg force) acting on 30mm

diameter steel washers.

These are all set into a pair of abutting 50x25 mm wood beams (shown in

orange on the track plan) which are glued into the foam base, aligned with

the top edge. Tests showed that using Everbuild StixAll building adhesive

resulted in a strong joint with the insulation board, adhering well to both

surfaces, and with excellent gap filling qualities; better than other

adhesives I tried.

Where the tracks cross board joints, they have been soldered to a 20mm wide strip of PCB, with

appropriate cuts in the copper surface to provide the track insulation. The cork underlay was removed

under the PCB and packing strips of grey-board are inserted under the copper strips, to match the

thickness of the cork. The PCB strips are then fixed with screws either side of each track, reaching down

into the wooden end beams. During soldering the tracks were aligned by eye. The vertical alignment of the

adjoining track ends can then be tweaked by adjusting the screws; compressing the grey-board.

The method of joining adjacent boards,

described above, has proved very satisfactory;

the magnetic clamps hold the baseboards firmly

and accurately together without the need for

any other clamping devices. To separate

adjacent baseboards a couple of large screw

drivers are needed to lever them apart!

The strength of the glued joint between the inset

wooden end beams and the insulation board has also

proved to be very robust, with no sign of separation.

The plywood side panels have also stayed firmly

attached to the sides of the insulation board, despite

some rough handling when forgetting they were only

glued!

The end result has been four very solid and fairly light

baseboards, easily carried by one person.

The basic topography of this corner section

completed with the canal lock and basin in

place. The hills have been built up with

scraps of the builders foam, overlaid with

low density filler and roughly painted for

areas of bare rock & moorland.

The area at bottom left will have a removable

raised part of the town, covering the point servos

for the hidden storage lines. At top right, these

servos and controller will be covered by a lift-off

section of moor and a signal box .

A tentative positioning of buildings is shown at left.

The full plan is shown here:

Update

Menu

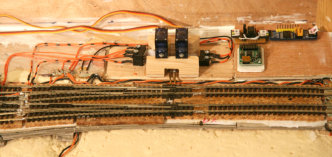

The DCC bus-wires are now in place and

wired to the tracks. The points servo

motors have been fitted, together with

micro-switches for the frog polarity and

switching of isolation sections. Note that

one of the servo motors has had the

thickness of the operating arm increased

( two extra part arms glued to it ) so as

to operate a second

micro-switch for the

two track isolation

sections of the

double track cross-

over.